ETFE molding

Information on the ETFE molding at SPN

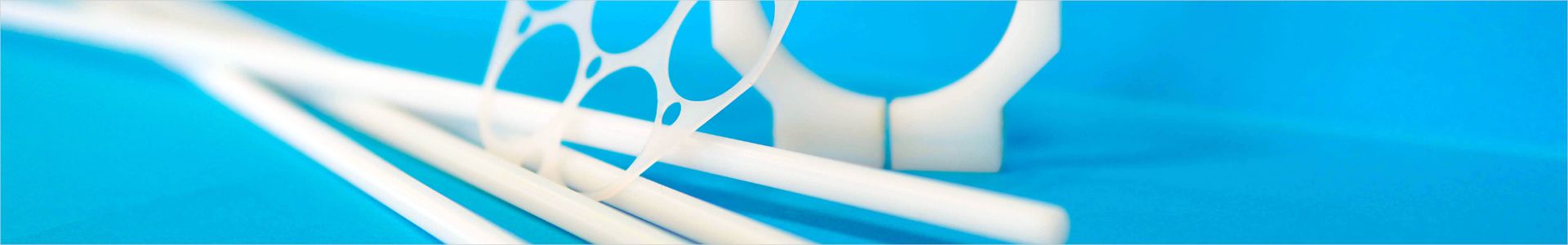

To manufacture blanks such as tubes, bars and plates, SPN uses the compression molding technique. The molding of ETFE – as well as other plastics – is one of the activities for which our company is renowned. Depending on the material used, compression is carried out cold (PTFE) or hot, especially for FEP or fluorinated ethylene propylene.

Generally, if we opt for ETFE molding, it is to allow slow cooling with compression during this cooling. This process allows optimum technical properties.

Ethylene tetrafluoroethylene or ETFE is highly resistant to UV radiation as well as gamma rays. This thermoplastic fluoropolymer also has the capacity to support 400 times its weight.

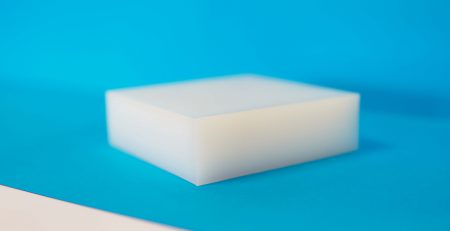

Semi-crystalline, this plastic allows light to pass through. Less expensive than glass and also lighter, 1.7 compared to 2.5. This recyclable material is weatherproof. This is why it is widely used in the construction and architectural fields. It is used in the manufacture of components such as joints and cladding. Although lower than PTFE, ETFE’s chemical resistance is not negligible. SPN machines this material (mostly known as TEFZEL®) to make gaskets in industry or aeronautics.