PCTFE rod

Information on PCTFE rods at SPN

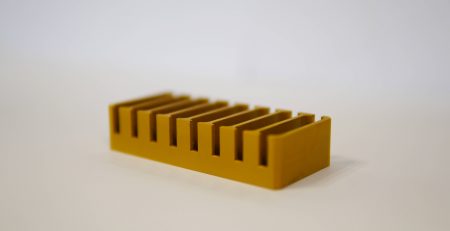

As a specialist in engineering plastics, SPN can supply the manufacturers with bars and rods in various materials including PCTFE (or PTFCE in French). In order to produce polychlorotrifluoroethylene rods in long dimensions, SPN uses the extrusion technique. This process allows SPN to offer customers bars with diameters between 7 mm and 20 mm. The bars are usually 1 or 2 meter long. SPN can also manufacture 3-meter long PCTFE bars to order. In general, extruded PCTFE is useful in the manufacture of seals with corrosive gases and requiring very low permeability.

To manufacture large machined parts (valve seats and non-return seals among others) and semi-finished products such as PCTFE tubes or bars, SPN also uses the compression molding process. This technique consists of first inserting the material into a mold, the dimensions and design of which meet the customer’s wishes. The mold is then heated according to specific parameters. It is then placed under a press. The compression is maintained throughout the cooling time. This process guarantees the quality of the finished products and a high degree of cristanility.

In addition to PTCFE, the specialist company SPN also manufactures rods in other polymers such as PFA, PI – Polyimide, PVDF, PSU and natural or filled PTFE.