Melting point PCTFE

Melting point PCTFE

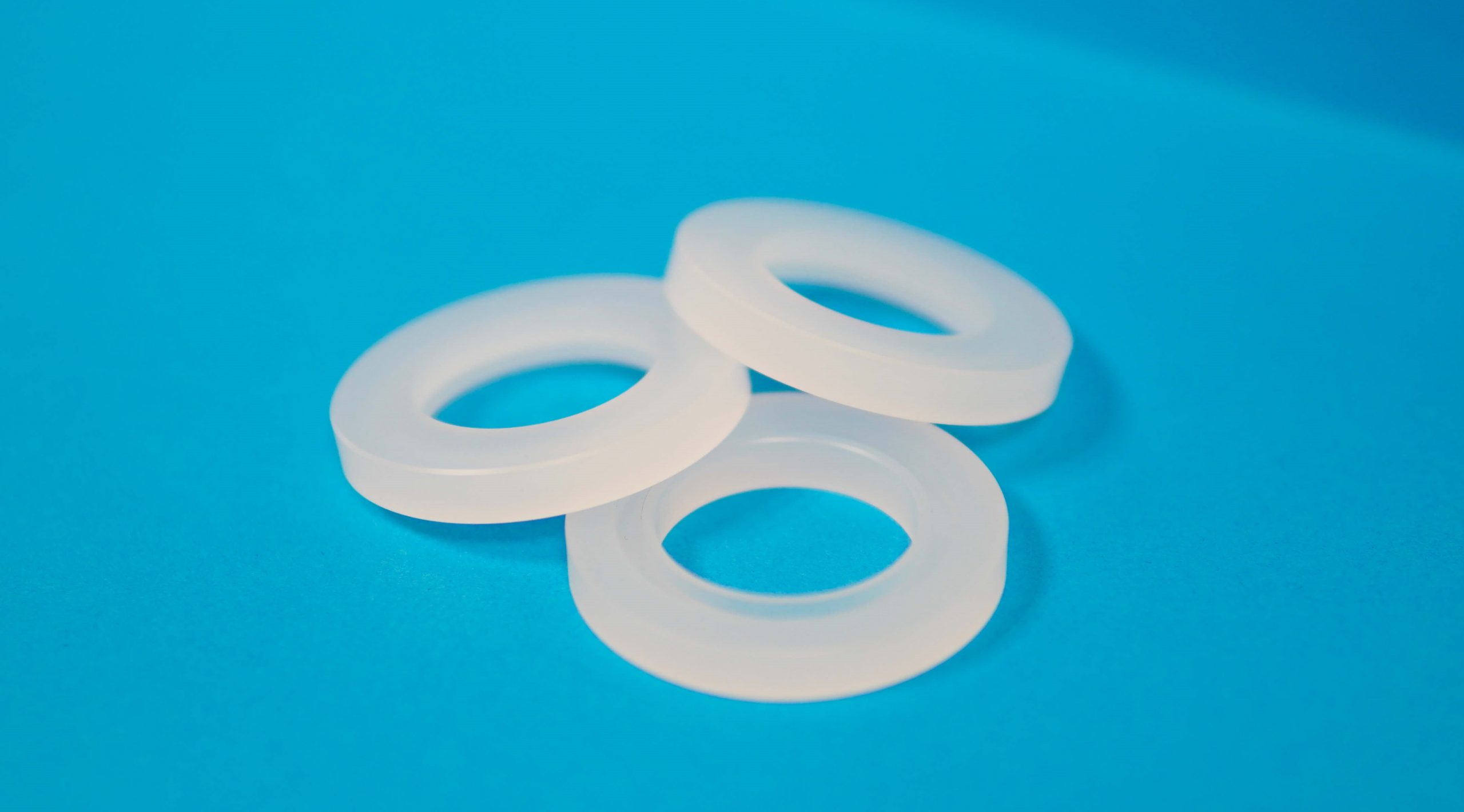

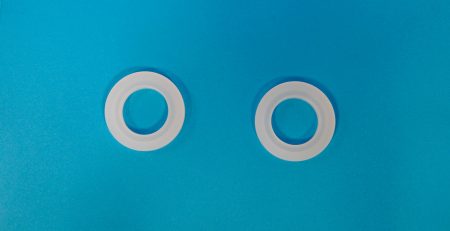

PCTFE differs from other high-performance plastics by its outstanding characteristics. Perfectly suited for use in industrial sectors such as aeronautics and cryogenics, this material has the ability to retain its mechanical properties even when subjected to cryogenic temperatures. Thanks to the chlorine atom, the PCTFE melting point is among the lowest of fluoropolymers. The melting point is between 210°C and 215°C. Moreover, this fluoropolymer has the advantage of not containing hydrogen and having a low coefficient of thermal expansion. In order to offer top quality components to the manufacturers, PN uses PCTFE or polychlorotrifluoroethylene, perfectly compatible with oxygen gas.

For 80 years, Société des Plastiques Nobles has been processing and machining high performance plastics to obtain semi-finished products such as tubes and bars and machined parts such as valve seats and seals. SPN also offers atypical products such as diaphragms, strips and films in standard or tailor-made dimensions. We produce prototypes of high-performance plastic components and can, if required, guarantee the series production of your parts. The components are manufactured in strict compliance with your specifications in order to meet your expectations and quality requirements. To transform and machine high-performance plastics, SPN uses various processes including turning.