Milling Polyimide

Milling Polyimide

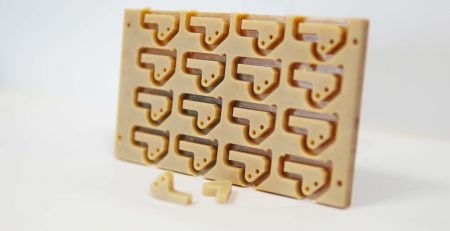

One of SPN’s specialities is the production of parts by milling. All plastic components can be milled. However, this process is reserved for parts that do not have an axis of revolution. The workpiece is fixed in a fixture or vice on a milling table. Excess material is then removed with a cutting tool. This can be done using a milling cutter, lathe or drill. The process results in a part with dimensions that fully meet the customer’s requirements. SPN carries out different types of milling: in 5-axis numerical control for complex components and conventional for simple components. The company offers Polyimide milling and other plastic materials.

Polyimide or PI is an infusible and crystalline polymer. Marketed under the trade name Vespel®, this material has extreme operating temperatures: continuous temperature from -270°C to +315°C, peak temperature at 550°C. This plastic can be presented in a thermo-hardened or thermoplastic form.

The polymer is appreciated for its perfect resistance to shocks, friction, creep and wear. Thanks to its low dielectric coefficient, it is an excellent thermal and electrical insulator. Chemically inert, the polymer remains intact in contact with refrigerant, chlorinated solvents, grease, lubricant or kerosene. The material is generally used for its high resistance to heat. It is inert when exposed to a temperature of 340°C. This plastic also benefits from interesting cryogenic properties down to -196°C. Its moisture absorption rate is almost nil and it has little degassing.