PVDF Turning

PVDF Turning

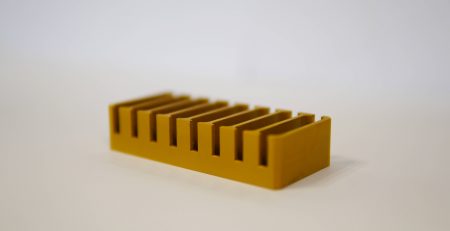

Machining operations such as PVDF turning are among SPN’s specialities. The company is also equipped with a selection of high-performance machines and tools to enable this operation. For turning PVDF and various plastic materials, SPN uses numerical lathes and conventional lathes in order to be able to machine the materials according to the customer’s requirements. The PVDF turning operation consists of rotating the workpiece by means of a chuck, a turret equipped with a cutting tool then removes the unnecessary material. The precision of the operation depends on the dimensions of the material and the means used.

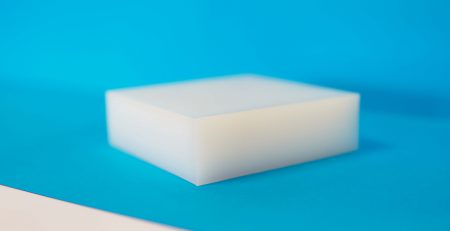

PVDF or polyvinylidene fluoride is a type of semi-crystalline, inert thermoplastic polymer. The material can be used over a wide temperature range from -20° to + 130°. It has excellent fire resistance and remains unchanged at temperatures up to 175°C. PVDF is also resistant to abrasion and UV action. Its main feature is its chemical stability. It is resistant to many chemicals, including oxidants, aromatic and aliphatic hydrocarbons, chlorinated solvents, halogens and aromatics. This thermoplastic polymer is used in the chemical industry for the design of tanks or pipes. It is mainly used as a protective barrier or insulation. The electronics industry uses it to insulate wires and piezoelectric elements. SPN is involved in the turning of various other high-performance plastics with good chemical resistance such as PTFE.