Milling PEI

Milling PEI

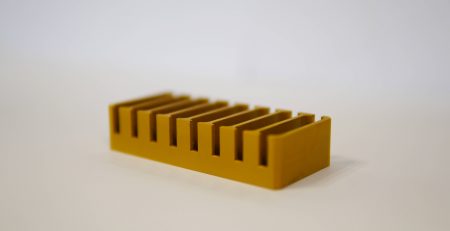

Milling is a process that SPN regularly uses for the manufacture of certain plastic parts. PEI, PFA or perfluoroalkoxy milling, PSU milling or Polysulfone milling: all plastics of any kind can be milled. In concrete terms, PEI milling – or milling of other materials – involves the removal of material by means of a rotating cutting tool. To do this, the technician fixes the material to be milled in a vice on a milling table or an assembly, as the case may be, and removes the excess material. This cut allows the dimensions of the parts to be obtained. Milling is mainly used in the manufacture of parts that do not have an axis of revolution. To manufacture simple parts, SPN teams use conventional milling technology. The 5-axis digital version of the process is useful when the parts to be designed are more complex.

PEI or Polyetherimide is a plastic material known for its outstanding resistance. Like polysulfones, PEI withstands high temperatures perfectly well. Thanks to its high dielectric strength, PEI is able to withstand a tensile strength of around 40 N/mm² at 175°C. This material also has outstanding insulating and mechanical properties. It also has the advantage of being resistant to high-energy radiation. PEI is one of the most commonly used materials in the design of medical imaging equipment. It is also frequently used in the electronics, aeronautics and chemical industries.