PSU Turning

PSU Turning

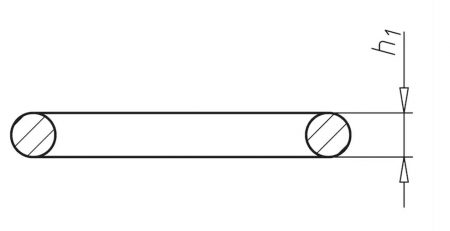

SPN specializes in plastic machining operations and has a selection of high-performance machine tools. Turning of plastic components such as PSU turning is one of its specialties. For this type of operation, the SPN team uses conventional and digital lathes according to customer requirements. Turning consists in machining plastic parts with a revolution axis by material removal. The plastic component is placed on a chuck and a turret equipped with a cutting tool cuts the material. In addition to PSU turning, SPN also turns various other high-performance plastics.

PSU or polysulfone is a thermoplastic material. It remains stable even when exposed to high temperatures, up to 150 °C in particular. Another special feature of PSU is its excellent creep resistance. It is also highly resistant to bending and tensile stress and has a high degree of rigidity. Polysulfone is an excellent electrical insulator and has high mechanical strength. It can be steam sterilized due to its high water resistance. This feature and its resistance to heat make PSU a highly sought-after material in the design of laboratory tools, particularly for anaesthesia equipment. It withstands beta rays, infrared, X-ray gammas and microwaves. Polysulfone is also used in the manufacture of components intended to be exposed to frequent washing and sterilization, such as filter plates, valves or pumps. Alloying PSU with fiberglass increases its dimensional stability and rigidity.