ETFE Turning

ETFE Turning

Equipped with high-performance machine tools, SPN offers various machining operations, including turning. The company works with many plastics, in particular ETFE. Among other things, SPN carries out ETFE turning from conventional or numerical lathes according to the customer’s specifications. Turning consists of machining the material and rotating it by means of a chuck. A turret equipped with a cutting tool is then used to cut the material. The precision of this operation depends on the size of the workpiece and the material.

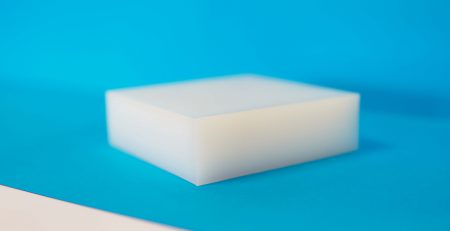

ETFE or Ethylene Tetrafluoroethylene is generally used as an alternative to glass. It allows light to pass through. It is lighter than glass with a density of 1.7. The density of glass is 2.5. ETFE is also appreciated for its high resistance, both to UV and gamma rays, but especially to cracks and impact. This thermoplastic fluoropolymer can support a load that is 400 times its weight. It is lightweight and can withstand a wide temperature range from -80°C to 155°C.

This reusable thermoplastic has good chemical resistance. It is one of the essential materials in the design of injected mechanical assembly parts, such as valves, fittings and pumps. It is also used in the chemical industry due to its resistance to continuous high temperatures. The material is also used in construction and architecture, particularly for the manufacture of seals. Easy to handle and light-transmissive, ETFE is also used in these fields for finishing.