PPS Turning

PPS Turning

PPS filming is one of the activities in which SPN specializes. The company is equipped with several high-performance machine tools to carry out this type of machining operation. The team uses both numerical and conventional lathes for this purpose, depending on customer demand. A chuck rotates the plastic parts and a turret then cuts the desired material with a cutting tool. The precision of this operation depends on the dimensions of the part and the technique used. SPN also turns other high-performance plastics such as FEP, EEK and PVDF in addition to PPS turning.

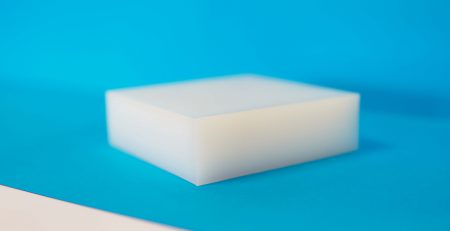

PPS or polyphenylene sulphide is a semi-crystalline plastic used as an alternative to metals and thermosetting plastics. It preserves its mechanical properties, such as stiffness, strength and creep resistance at high temperatures. It remains unchanged at 270°C. This polymer also has good chemical resistance. PPS is insoluble, immersed in most known solvents heated below 200 °C. PPS absorbs little water. It is also an excellent electrical insulator. In addition to its electrical properties, it has high dimensional stability. This plastic also has the ability to retain its electrical and mechanical properties even at cryogenic temperatures.

PPS is mainly used in the design of electronic and electrical components, including plugs, coils, relays, multipoint connectors, etc. In the medical sector, it is used in the manufacture of surgical instruments. The chemical industry uses it in the manufacture of valves, sockets, pump housings, etc.