POM Turning

POM Turning

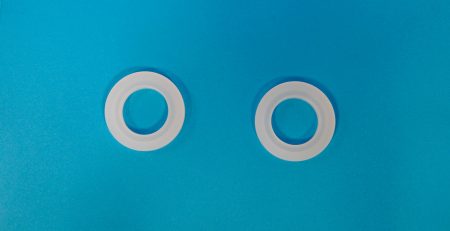

Entrust plastic machining operations to SNP. The company specializes in turning. The company is equipped with various machine tools for this type of operation. The SPN team uses numerical lathes as well as conventional lathes to machine plastic parts. Everything depends on the customer’s specifications. Among other things, SPN carries out POM turning. To do this, the part is placed on the lathe which is operated by a chuck. A turret then removes the excess material with a cutting tool.

POM or Polyoxymethylene is a semi-crystalline white thermoplastic polymer that can be dyed. It exists in the form of homopolymer (POM-H) and copolymer (POM-C). The POM-H form has good rigidity and creep resistance. It is also very hard and resistant to traction. The material is also appreciated for absorbing only very little moisture. This POM form is used in the manufacture of highly stable construction parts and in the design of precision parts for machines.

The POM-C form, on the other hand, is resistant to strong bases. Thanks to its elasticity, it does not crack. POM-C remains unchanged even when subjected to hydrolysis. These various characteristics make this thermoplastic a popular material in the food industry. But POM in general is used in the automotive, textile and mechanical engineering industries for the manufacture of wheels, rotors, pinions, valve housings, etc.