PEEK Turning

PEEK Turning

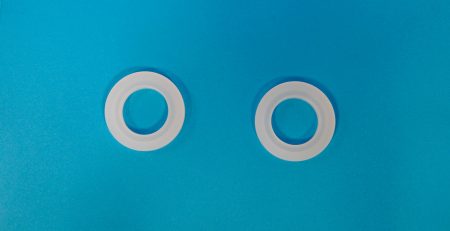

PEEK is one of the components that SPN offers for turning. This delicate operation involves the machining of plastic parts through material removal. Only parts with an axis of revolution can be turned. For turning PEEK – and other plastics – SPN has purchased machine tools with proven performance. These tools include MAZAK and MORI SEKI numerical lathes as well as a conventional Cazeneuve lathe. In addition to PEEK or polyetheretherketone, SPN also carries out PTFE or polytetrafluoroethylene turning, PFA or perfluoroalkoxy turning and PEI or Polyetherimide turning. SPN also handles the turning of other materials such as polyimide, which, like PEEK turning, allows the production of parts resistant to very high temperatures. These materials also benefit from good chemical and mechanical performances.

PEEK is a thermoplastic with several qualities. In addition to being very rigid, this polymer has the advantage of increased resistance to high but constant temperatures of around 250°C. It is resistant to chemical attack – in the short and long term – and is highly resistant to hydrolysis and creep. PEEK or polyetheretherketone is also wear-resistant. It also has a low moisture absorption capacity and is inert to high-energy radiation. PEEK is a polymer widely used in the aerospace, medical and automotive industries. The mechanical strength of this material is also useful in the semiconductor industry.