PCTFE machining

PCTFE machining

For 80 years, the Société des Plastiques Nobles or SPN has been a reference in the transformation and machining of high performance materials such as PCTFE. At SPN, processing is carried out using creep, extrusion and compression moulding processes. Semi-finished products such as bars, tubes and plates are machined either by cutting, milling or turning.

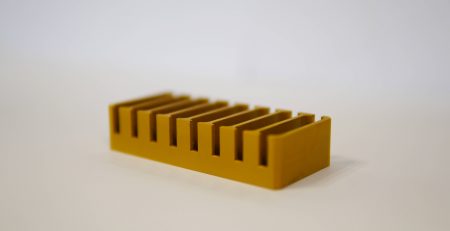

Milling is one of the PCTFE machining techniques we offer. Applicable to all noble plastics, this technique allows the removal of material from an element, via a rotating cutting tool, to obtain the dimensions required in the specifications.

Milling only allows the manufacture of parts that do not have a rotating axis. Depending on the complexity of the parts, SPN can use conventional milling or 5-axis numerical control.

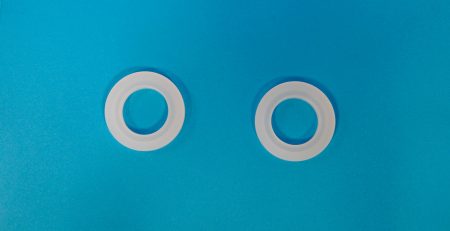

SPN also has a large number of machine tools for turning plastics such as PCTFE. Depending on the technical specifications required by customers, SPN uses either numerical lathes – DMG MORI and Mazak brands – or conventional lathes.

PCTFE machining using turning technology allows the production of perfectly sealed components with high mechanical performance. The components obtained by PCTFE turning are highly resistant to very low temperatures.

According to the technical characteristics specified by the customer, SPN selects the most suitable manufacturing process. We make sure that we comply in all points with the elements indicated in the customer’s specifications.