Creep problem with PTFE, PCTFE is the solution

PTFE is used in many seals because it has remarkable properties especially in the industrial valves, cryogenics and chemical sectors. PTFE is used in extreme environments such as low temperatures, corrosive chemicals, or low friction coefficient.

One of the major defects of PTFE is creep, i.e. deformation when subjected to pressures and time. To overcome this defect, PTFE can be compounded (addition of another material to improve certain properties of PTFE) especially with glass fiber. However, compounded PTFE is also sensitive to creep to a lesser extent.

Under these conditions, many manufacturers in the valve or pump market use the PTFE derivative called PCTFE (polychlorotrifluoroethylene or Kel-F). This material reduces PTFE creep problems in seals. It also provides better dimensional stability.

PCTFE has the same advantages as PTFE including broad chemical compatibility and similar temperature ranges. It is particularly used at high pressures with a need for low leakage rate (very low gas permeability). PCTFE also has excellent flammability resistance (flammability rating is V0 according to UL94) and high moisture repellency. It is particularly resistant to very corrosive or acid gases (especially Helium or Hydrofluoric acid). This PCTFE complies with FDA, European food 10/2011 and is compatible with oxygen gas applications (BAM certificate).

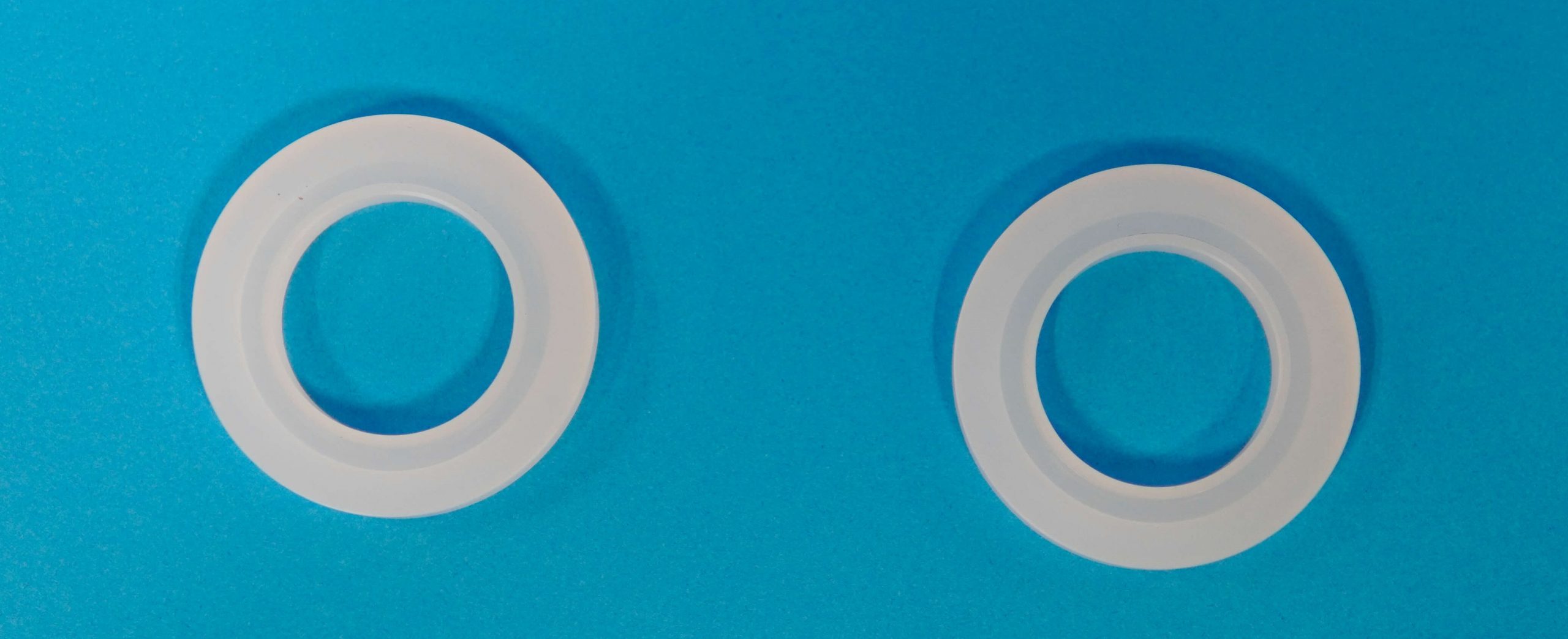

SPN offers semi-finished products made of PCTFE (Voltalef, KEL-F) or machined parts such as seals, valve seats, non-return seals, etc.

Do you need further information? Please contact us!