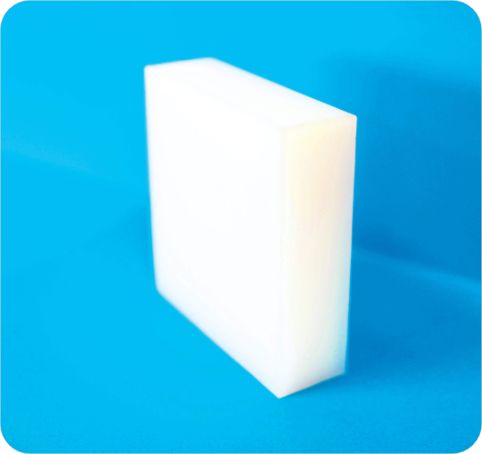

PVDF

[vc_row][vc_column][vc_column_text] PVDF Material (polyvinylidene fluoride) Key features: Excellent chemical resistance Fire-resistant UV and radiation stability PVDF or polyvinylidene fluoride is a highly inert, semi-crystalline thermoplastic polymer. This material can be handled over a wide temperature range, from -20°C to + 130°C. It is very fire-resistant and remains unalterable even under a heat...