ETFE milling

ETFE milling

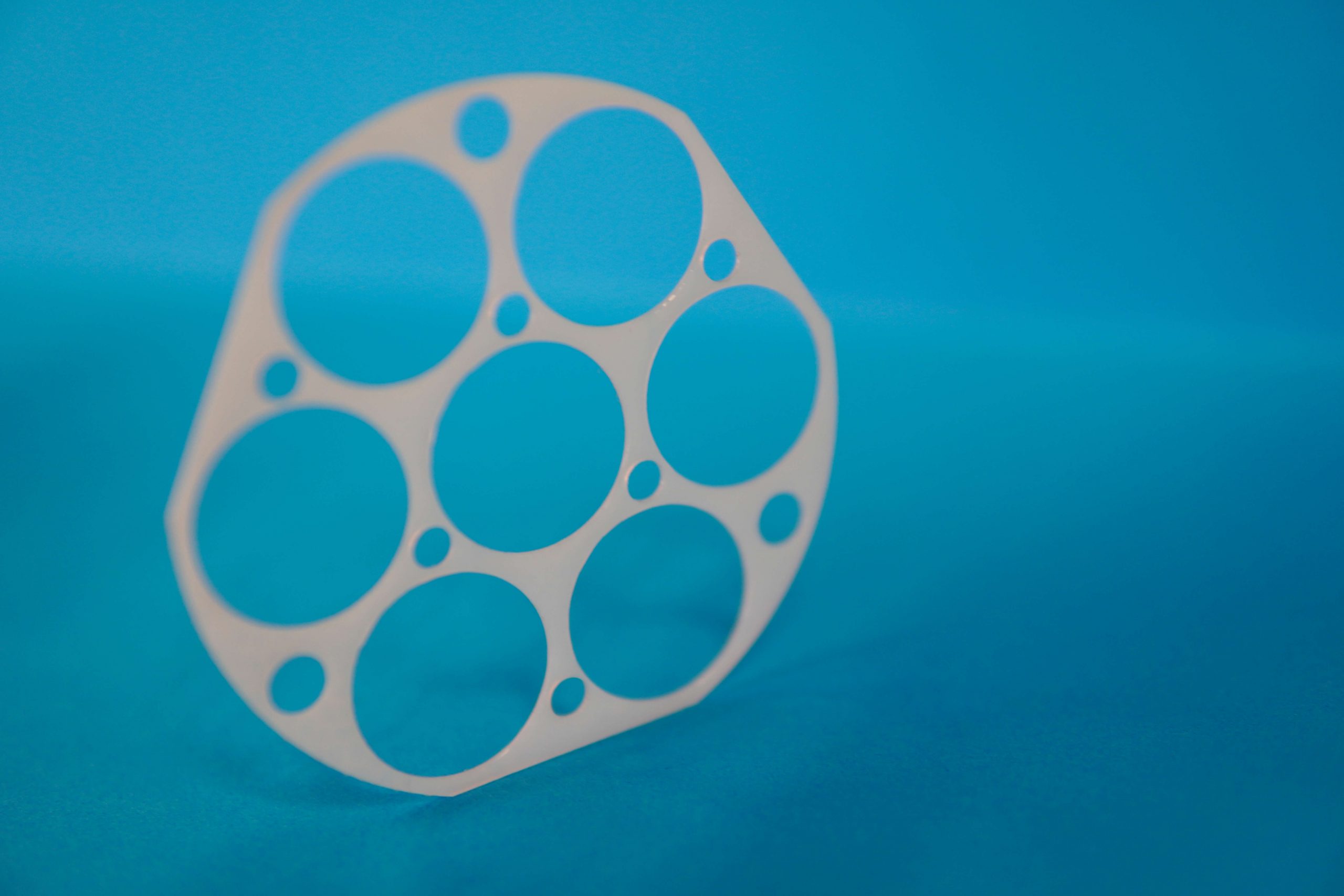

Milling is one of the processes used by SPN for the design of certain plastic parts. It is an operation reserved for parts that do not have an axis of revolution. It consists in fixing a block of raw plastic in a vice or a special table assembly. A rotating cutting tool is then used to remove material. Milling allows the design of dimensions according to the customer’s request. SPN specialises in many types of milling, including 5-axis CNC milling for complex parts and conventional milling for simple parts. All materials can be milled. SPN offers ETFE milling in particular.

ETFE or Ethylene Tetrafluoroethylene is a material appreciated for its ability to transmit light perfectly and its good resistance to UV and gamma rays. It is therefore an excellent alternative to glass and is also highly resistant. It can withstand a load 400 times heavier than it. ETFE is stronger than glass but lighter with a density of 1.7. Ethylene tetrafluoroethylene can withstand large temperature variations. It does not change over a range of -80 °C to 155 °C. This material is recyclable and has high chemical resistance.

This plastic is highly sought-after for the design of components of injected mechanical assemblies, such as fittings, valves or pumps. It is very popular in the chemical industry and in the construction sector. ETFE is used in the field in the manufacture of seals and coatings.