FEP, a perfect material for the use of UVC lamps

FEP, a perfect material for the use of UVC lamps

Disinfection of water, work surfaces, air or objects can be critical in some circumstances and there are many limitations to the use of chemical disinfectants. UVC lamps can overcome these disadvantages. However, the use of this equipment may require some sensitivity. FEP plastic is used to overcome the fragility of the lamps, without affecting the germicidal properties of the radiation. For example, FEP allows the UV lamp to be sheathed and keeps debris in the lamp in case of breakage.

FEP, a polymer compatible with the germicidal properties of UVC rays

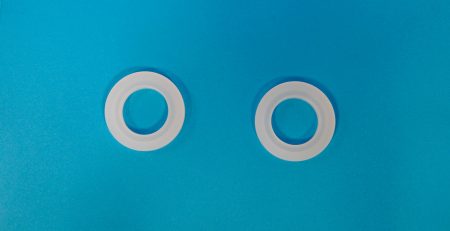

FEP is a fluorinated plastic that is resistant to physical stresses and deformations such as creep, traction and wear, as well as being stress-cracking resistant. This polymer is inert to UVC. In addition, FEP (depending on thickness) allows nearly 97% of this radiation to pass through. These are properties that are very much appreciated for optimising the use of UVC lamps. Other materials such as PCTFE have a better transmission to UVC but cannot be used as a heat-shrinkable sheath.

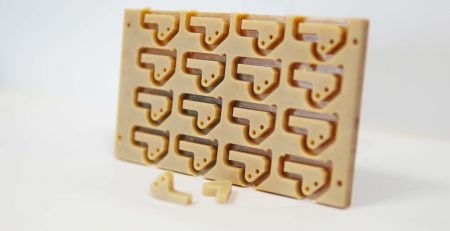

Whether UVC lamps are low or medium pressure or use a mercury amalgam alloy for higher wattage, they consist of one or two bulbs. Depending on the model, the bulbs may be soft and have a UVC transmission efficiency or harder. Although some types of bulbs are less likely to break than others, to make the lamp more resistant and to prevent glass fragments or mercury from coming into contact with the object to be disinfected in the event of breakage, it can be coated with an FEP film. As this plastic is permeable to UVC, it does not affect the germicidal action of the rays, which is the main use of lamps emitting this type of radiation.

UVC, a proven means of disinfection

Together with UVA and UVB, UVC is one of the rays emitted by the sun. With a short wavelength between 100 and 280 nanometres, they are absorbed by the atmosphere and therefore do not pose a danger to human health, but are formidable against bacteria, viruses, yeasts and moulds. In contact with microorganisms, UVC alters their cell membranes and nuclei. This causes mutations and kills up to 99% of microbes on surfaces and in the air.

UVC disinfection is mainly used when conventional methods using chemicals such as chlorine or simple washing are not possible. UVC lamps are therefore used in many applications, such as :

- water purification and treatment (city water tank, well, canal, aquarium, etc.).

- air purification

- sterilization of medical instruments, hospital work surfaces

- disinfection of everyday objects such as mobile phones

- food and beverage manufacturing.

The use of UVC has other advantages. They are generally more environmentally friendly since they do not use chemicals and do not emit by-products. This equipment is also easy to handle. However, safety regulations must be followed to ensure safe use.