FEP molding

Information on the FEP molding at SPN

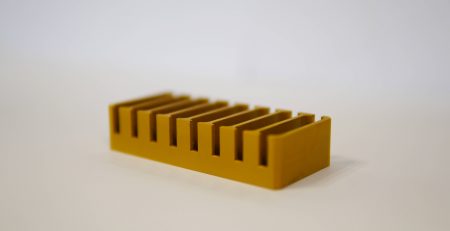

SPN specializes in plastic compression molding operations. Depending on the type of plastic to be processed, compression is carried out at room temperature or high temperature. SPN uses the compression molding process to produce blanks of various shapes and sizes. Plastic plates, bars and tubes are thus offered to customers. SPN manufactures these three types of semi-finished products (tubes, bars and plates), although tubes are the most popular. They are cheaper to produce and require little raw material. SPN can manufacture tubes with diameters up to 500 mm. Depending on the case, the machining of the blanks is carried out either in-house or by the customers themselves.

FEP molding is common within the company. FEP or fluorinated ethylene propylene is characterized by its unparalleled thermal resistance. Even after use at temperatures between -270 °C and 240 °C, it still retains its mechanical properties. Compared to other fluorinated plastics, this material is highly resistant to traction, creep and wear. It is also resistant to environmental stress cracking and UV radiation. Made from a mixture of hexafluoropropylene and tetrafluoroethylene, FEP has a relatively low coefficient of friction. It also absorbs little moisture.

Thanks to these qualities, FEP is widely used in the manufacture of fittings, various pipes and sealed parts such as joints. In the aerospace industry, this plastic material with proven performance is used to protect cables.