Milling PA66

Milling PA66

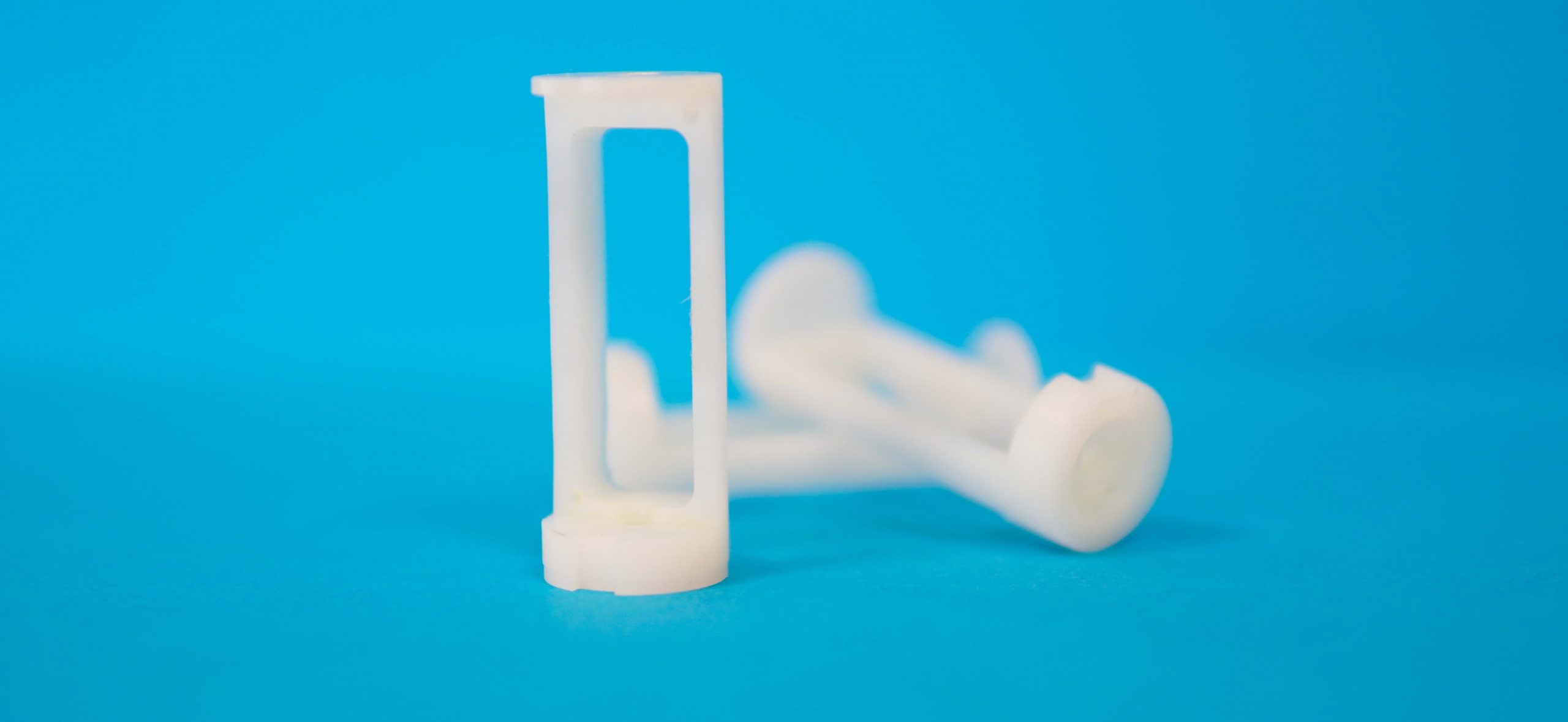

Some plastic parts can be manufactured using milling technology. This operation is dedicated to parts that do not have an axis of revolution. It consists of holding the material in a fixture or vice on a milling table. A cutting tool, such as a milling cutter, a lathe or a drill, then removes the material in order to obtain dimensions in accordance with the customer’s request. Conventional milling and 5-axis CNC milling are among the techniques used by SPN for milling. This technique can be applied to all plastic materials. SPN carries out, among others, PA66 milling.

SPN only machines PA6 and PA6.6 for industrial applications. PA or polyamide has perfect mechanical resistance and is difficult to wear out. It is also internally resistant to petroleum products and common solvents. These characteristics make it a widely used material in many sectors. For example, it is required in the design of products that need to be highly resistant. This is the case for fibres or engineering parts. Polyamide is also used in the automotive industry for the manufacture of fittings, gears, etc.

However, PA is sensitive to moisture. Moisture alters its mechanical and dimensional characteristics. PA parts must therefore be stored with great care. The plastic component requires protection against weather, UV and light when used indoors. It must also be protected from an atmosphere that is too dry, as this condition can make it rigid and brittle.