Milling PSU

Milling PSU

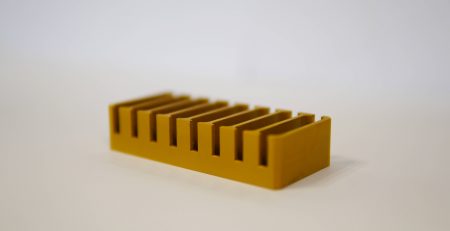

SPN uses milling to manufacture parts that do not have an axis of revolution. Milling consists of fixing a plastic block in a vice or a mounting on a dedicated table. A cutting tool such as a milling cutter, a drill or a drill bit then removes the excess material. The operation makes it possible to cut dimensions according to the customer’s request. SPN carries out various types of milling, i.e. conventional milling for simple parts and 5 axis CNC milling for delicate parts. All plastic components can be milled. SPN masters among others PSU milling.

PSU is a thermoplastic that has the ability to remain stable even when exposed to high temperatures. It is continuously stable at temperatures of up to 150 °C. Up to 180 °C, however, the stability of the material is momentary. This plastic is also very resistant to creep. It also withstands bending and tensile stress. PSU is a very stiff material. Also known as polysulfone, this thermoplastic has very good mechanical strength and is an excellent electrical insulator. It can be steam sterilized thanks to its very good water resistance. PSU remains intact in contact with alkalis, paraffin oils and inorganic acids.

Gamma X-rays, beta rays, microwaves and infrared rays have no effect on the PSU. It is highly valued in the medical and food sector due to its resistance to hydrocarbons. This material is also used in the manufacture of laboratory and kitchen equipment due to its impermeability and heat resistance.