Milling PVDF

Milling PVDF

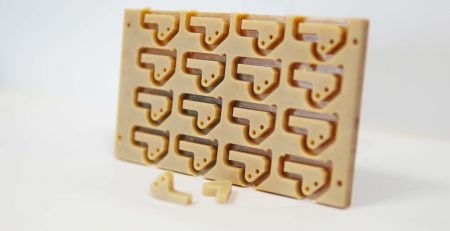

SPN uses milling for the design and machining of workpieces that do not have an axis of rotation. Depending on whether the finished part has a simple or more complex design, the company uses conventional milling or 5-axis CNC milling. Milling is a technique applicable to all plastics. For example, SPN carries out PVDF milling. This operation consists of holding the raw material in an assembly and removing the material using a dedicated tool. This can be done using a lathe, drill or milling cutter. The process makes it possible to obtain parts with dimensions corresponding to the customer’s requirements.

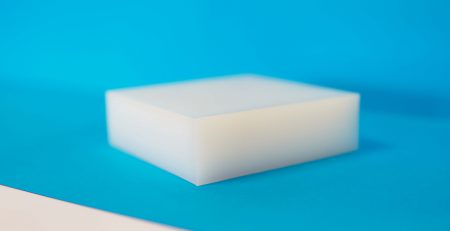

PVDF or polyvinylidene fluoride is a highly inert, semi-crystalline plastic component. This thermoplastic polymer can be used over a very wide temperature range, from -20° to + 130 °C. PVDF is resistant to fire and heat up to 175 °C. The material is inert to various chemicals such as oxidants, aliphatics, aromatics, chlorinated solvents, inorganic acids, etc. However, this plastic reacts to very basic solutions such as ketones and esters. However, PVDF is resistant to abrasion and to various types of radiation such as UV light.

This thermoplastic is used in various fields, including the chemical industry for the construction of tanks, pipes and accessories. It is also used as a protective barrier or insulation. For example, it is in great demand in the electronics industry. In the latter case, PVDF can be used to insulate wires and piezoelectric elements.