PCTFE datasheet

PCTFE datasheet

Enclosed is the PCTFE datasheet

PCTFE or polychlorotrifluoroethylene is one of the noble plastics most used in the sectors using in special and corrosive gases. Valve and valve manufacturers also often use this polymer for the manufacture of seals. This is mainly due to the advantageous technical properties of PCTFE.

Low gas permeability, PCTFE has outstanding mechanical properties, which it retains even when exposed to cryogenic temperatures. This fluoropolymer has both a high moisture repellency and a significant resistance to flammability. This material is also known for its creep and tensile strength. PCTFE differs from PTFE – whose formula is similar to that of PCTFE – thanks to an additional chlorine atom. It is this element that gives it its low melt index.

PCTFE also differs from PTFE by its low coefficient of thermal expansion. This thermoplastic is able to maintain its dimensional stability despite exposure to extreme temperatures ranging from – 240 °C to + 150 °C. PCTFE is also resistant to attack by oxidizing agents. Thanks to a totally hydrogen-free formula, this material remains intact despite the aggressive nature of certain active ingredients contained in chemical products.

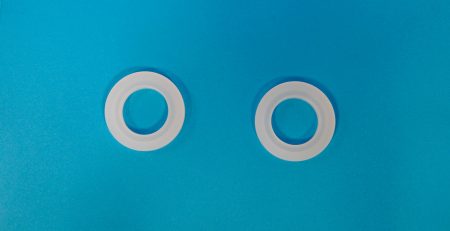

Depending on customer requirements, SPN transforms and processes to obtain semi-finished products such as bars, tubes and plates as well as machined parts such as non-returnable seals and gaskets.