PCTFE milling

PCTFE milling

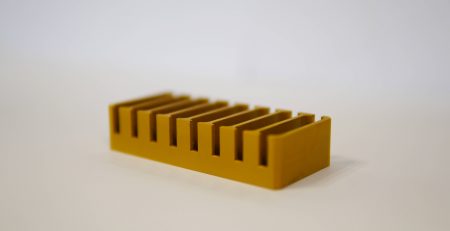

Some plastic parts are designed using milling technology. This is done by fixing a blank in a fixture or vice on a milling table and removing the plastic component with a cutting tool which can be a milling cutter, a drill or a lathe. Milling is reserved for parts with no axis of revolution. SPN carries out different types of milling operations. This is the case of milling in 5 axis numerical control. It is dedicated to complex parts. Conventional milling is recommended for simpler parts. Milling can be used on all plastic materials. SPN carries out among others PCTFE milling.

PCTFE is a fluorinated polymer appreciated for its physical and chemical properties. Its chemical composition is close to PTFE, but it has an additional chlorine atom. The latter gives it a low melt index. Its resistance to flames is also very appreciable. PCTFE is also permeable to gas and moisture. It has a low coefficient of thermal expansion. This plastic shows excellent resistance even in the event of significant temperature changes over a range of -240 °C to + 150 °C. It remains intact under the action of certain chemicals and oxidizing agents.

SPN offers a selection of semi-finished products made of PCTFE such as rods, plates or tubes. The latter can be worked to obtain valve seats, non-return seals and gaskets and other parts used in the aeronautics and cryogenic industries.