PCTFE Properties

SPN currently produces a dozen transformable materials. Among them, PCTFE, a fluorinated polymer has exceptional properties. Thanks to SPN’s expertise in plastics processing and machining, many reliable and high-performance products are produced from PCTFE for critical applications.

PCTFE properties can meet many industrial needs, especially when there are constraints of low temperature, high pressure, low leakage rate or corrosive and hazardous products.

PCTFE is the acronym used to designate the fluorinated polymer called polychlorotrifluoroethylene. For the record, it was German scientists Fritz Schloffer and Otto Scherer of the IG Farben Company who discovered PCTFE in 1934. Since then, many commercial names have appeared for PCTFE. Kel-F® from 3M is the best known name. But PCTFE is also known by other names, such as Voltalef® or Neoflon®.

Unlike PTFE, which is a tetrafluoroethene, PCTFE is a thermoplastic chlorofluoropolymer: it is a homopolymer of chlorotrifluoroethylene. One of the properties of PCTFE, but also one of its remarkable features, is its oxygen compatibility with a BAM certificate. But there are other PCTFE properties that make PCTFE an exceptional material. Among these properties, we can mention:

- its repulsion to moisture and water, its low coefficient of thermal expansion,

- its UL94 flammability rating of V0, its near perfect gas permeability, and

- its chemical stability, which makes it resistant to attack by corrosive products and to oxidation.

But what makes PCTFE exceptional is its resistance to cryogenic temperatures. PCTFE remains stable at low temperatures down to -240°C. Thanks to all these outstanding properties, PCTFE is used in many applications and industries.

PCTFE properties to meet critical requirements

PCTFE can be processed by compression molding or extrusion to produce high performance sealing products. Common applications that require PCTFE properties include the manufacture of Aclar® pharmaceutical blister packs, chemical sealing components, etc. Thanks to all its properties, PCTFE is appreciated in the technological industrial sectors, including cryogenics, hydrogen, or aeronautics.

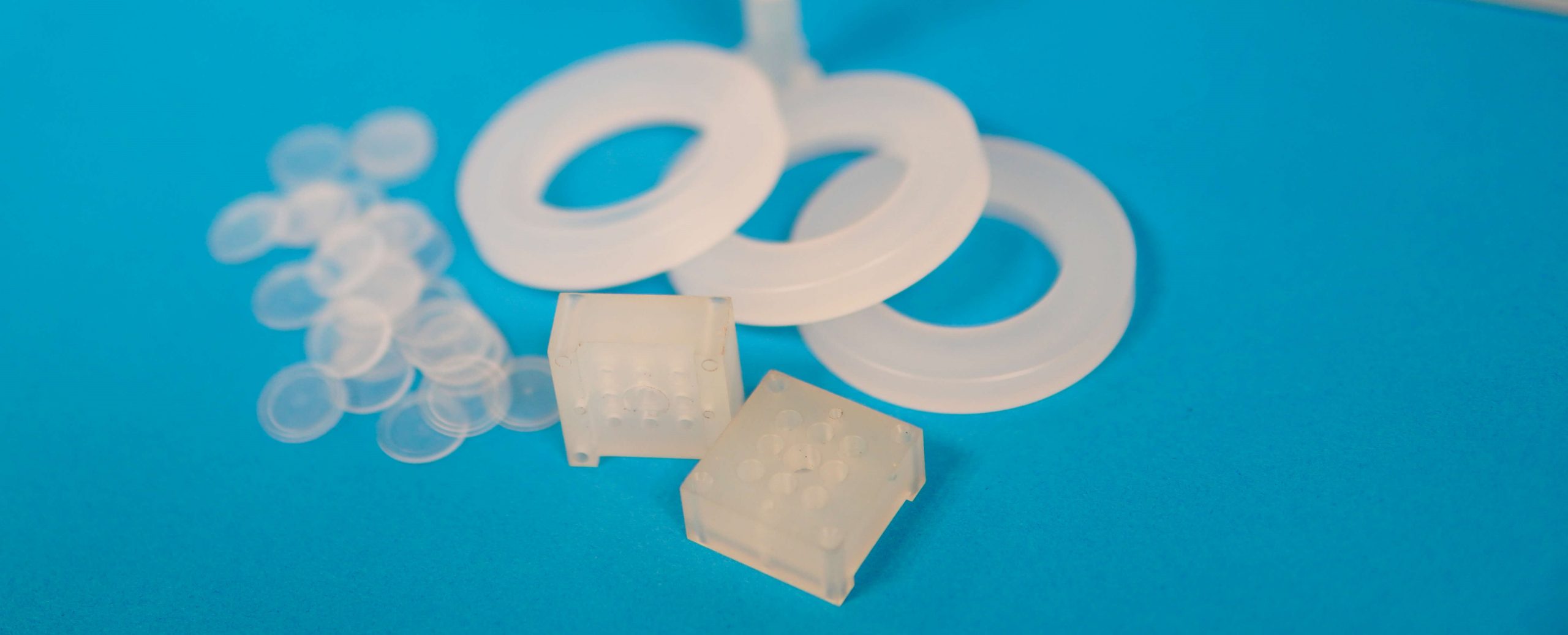

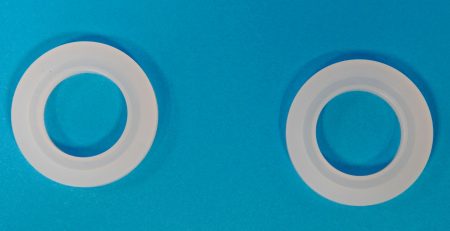

For all your sealing component needs, SPN provides you with very high performance PCTFE products:

- as a blank: bars, rods, tubes and plates;

- as a component: seals, washers and other plastic components according to drawings.

Thanks to its expertise in the field and the technologies used for the transformation and processing of plastic materials, SPN manufactures custom-made components adapted to any sealing problem. Talk to us about your projects and we will propose solutions that meet your needs.