PEEK milling

PEEK milling

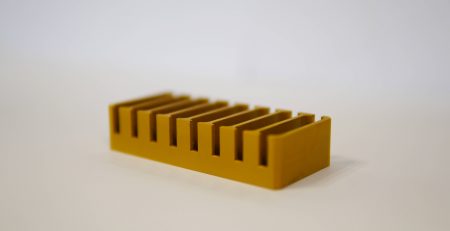

Milling is a process used by SPN for the design of parts that do not have an axis of rotation. This operation consists of fixing a block of raw plastic in a vice on a milling table or a fixture and removing the unnecessary material with a rotating and cutting tool such as a milling cutter, drill or lathe. Milling produces a part with dimensions according to the customer’s requirements. To create these parts, SPN can use two techniques, namely 5-axis CNC milling and conventional milling used respectively to obtain complex and simpler parts. All plastic components can also be milled. SPN uses PEEK milling, among other techniques.

Polyetheretherketone or PEEK is a rigid polymer with a high melting temperature of 340 °C. It is inert up to 250 °C. This plastic component is highly resistant to chemicals and hydrolysis. At room temperature, no organic solvents can dissolve polyetheretherketone, for example. It is also resistant to creep, even at high temperatures. It is also very resistant to wear and abrasion. Its low moisture absorption and low coefficient of friction also make PEEK a very popular material.

PEEK is suitable for use in industrial sectors requiring high performance and good mechanical strength. It is used in the medical, electronics, automotive, aerospace and semiconductor industries. Compared to other metals, the density of this material is very low. This is why PEEK is used as an alternative to metal components in the aeronautics sector. Its special features allow a significant saving in fuel.