PES milling

PES milling

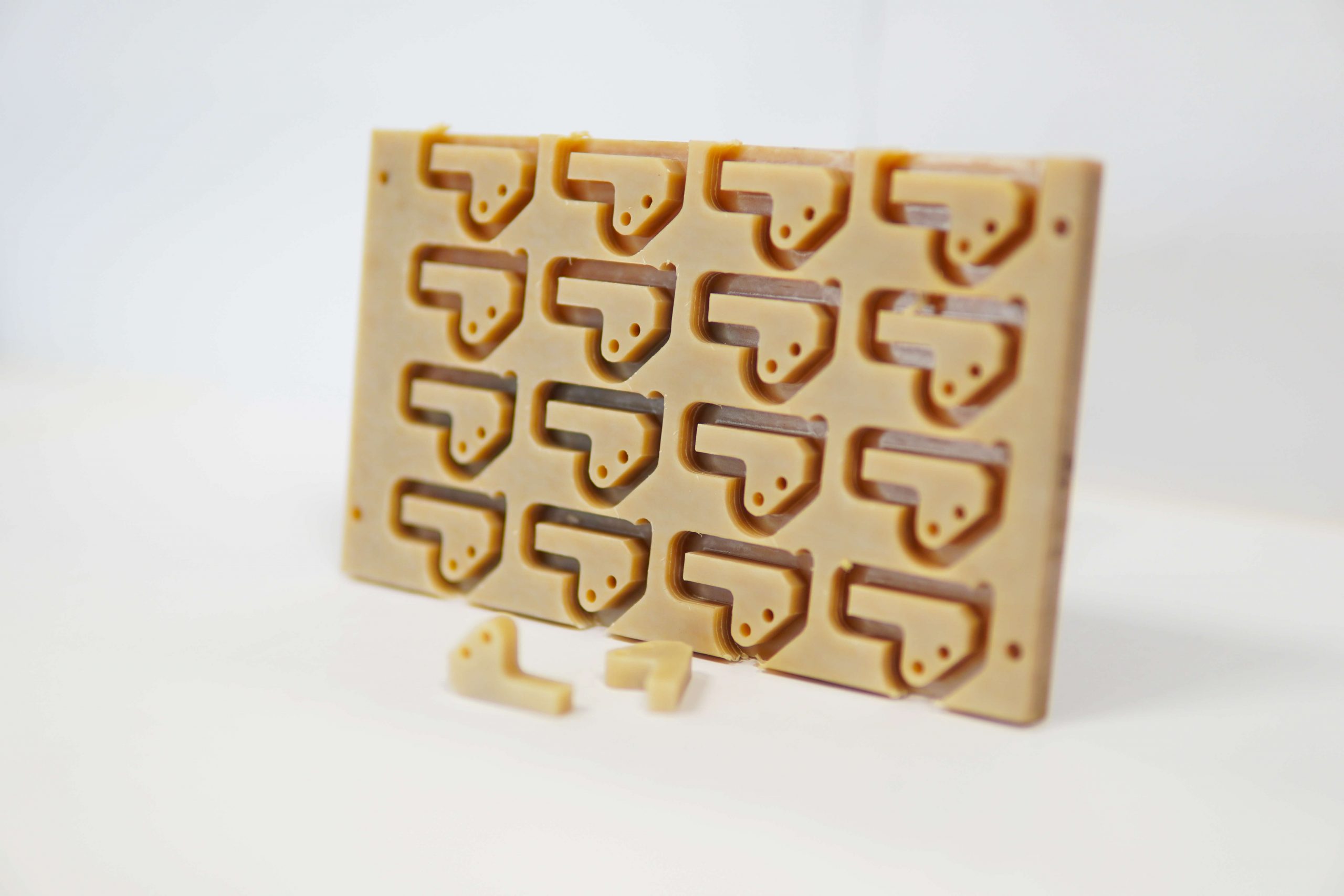

SPN carries out milling for the manufacture of certain parts used in different sectors. This operation is dedicated to parts that do not have an axis of revolution. It consists in fixing a blank in a vice on a milling table or an assembly. A cutting and turning tool then removes the unnecessary material to obtain a part with ribs. Depending on the complexity of the part, SPN uses two techniques. Milling in 5-axis numerical control makes it possible to produce parts with a lot of detail. Conventional milling, on the other hand, is used to manufacture simpler parts. All plastic components can be milled, just like PES. For PES milling you can use SPN.

Also called polyethersulfone, PES is a sulfide thermoplastic with high dimensional stability. It is resistant to high temperatures and has a low coefficient of thermal expansion. PES is highly resistant to impact and creep. Even at 100 °C, the material retains its physical properties. It also retains its properties at low temperatures. The plastic also has a tensile strength of 76 N/mm². It has low resistance to UV radiation and does not react to beta and X-rays. Plastic is an excellent thermal insulator and has a perfect dielectric constant.

PES is recommended for the manufacture of mechanical parts such as pumps, housings and valves. It is also a useful material in the medical sector thanks to its excellent resistance to chemicals and hydrolysis. It is also used in the manufacture of control plates for dialysis machines and anaesthesia equipment.