PFA milling

PFA milling

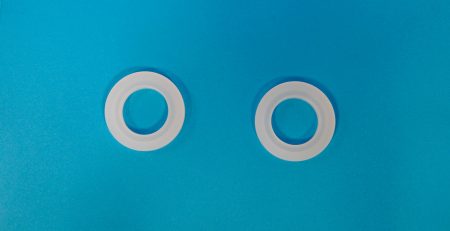

Depending on the customer’s requirements, SPN uses different processes for the production of plastic parts, such as milling. This operation is reserved for parts without an axis of revolution. The process consists of fixing a plastic block in a vice or a fixture on a milling table. A rotating cutting tool, such as a milling cutter, lathe or drill, is used to remove the material to trace the dimensions of the part according to the customer’s requirements. SPN carries out two types of milling. 5 axis CNC milling is used for the production of complex parts and conventional milling is used to create simpler parts. The company carries out milling of all plastic materials, including PFA milling.

PFA or perfluoroalkoxy is a thermoplastic polymer with characteristics similar to PTFE. It can be handled over a wide temperature range from -220 °C to 260 °C thanks to its perfect heat resistance. This fluoropolymer is inert to many solvents such as ketones, acids, alcohols, hydrocarbons or bases. It is resistant to UV rays and benefits from almost zero moisture absorption.

This plastic material is widely used in areas that require the production of parts with a very low level of moisture absorption, such as in the pharmaceutical and semiconductor industries. PFA is also appreciated in electrical applications because of its low electrical constant. This plastic is also used as a coating when exposed to an environment with extreme chemical, thermal and mechanical stress.