PFA Properties

PFA is a material processed and machined at SPN. It is a material whose properties are perfect for many sectors such as medical or chemical. Among the properties of PFA, we particularly appreciate its non-stick properties, its chemical compatibility with many products and its wide range of operating temperatures. But like all other high-performance materials, PFA offers many other advantages. This makes it possible to meet the requirements of a wide range of industries.

PFA properties make for reliable products

PFA or perfluoroalkoxy belongs to the family of fluoropolymers. It is flexible, clear, fairly transparent with a bluish glow. Invented by DuPont, PFA has several trade names, including Chemours’ Teflon®-PFA, AGC’s Fluon®-PFA and 3M’s Dyneon®-PFA. The properties of PFA are similar to those of PTFE and FPE, with a few differences: for example, PFA can be melted for conventional molding and injection processes.

Parts made with PFA are used in severe or critical environments where a service temperature range may be above 200°C.

But PFA properties are also :

- its high insulating power: it has a low dielectric constant,

- a remarkable chemical inertia, a non-stick power, a good resistance to UV, so PFA has a low aging rate,

- a water absorption rate strictly lower than 0.01%: it is a non-hygroscopic material.

Finally, for the food sector, PFA has obtained FDA – Food and Drug Administration – compliance. This standard concerns more particularly all materials in contact with food such as polymer coatings, adhesives, papers or cardboards.

PFA is used in many applications

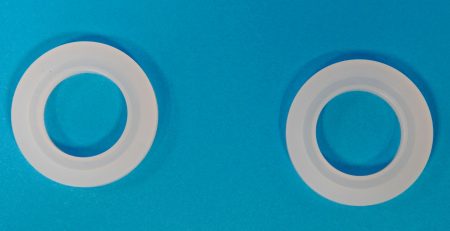

As a thermoplastic polymer, PFA can be processed: by compression molding and extrusion or pulled, as in the manufacture of pipes or tubes. Various parts and products are manufactured from PFA: pipes, hoses, sheaths, fittings, rods, rings, bellows, sheets, linings, etc. Many sectors use PFA for the manufacture of various high performance parts: the pharmaceutical and medical industries, laboratories, semiconductor and electrical applications, chemical industries, or even manufacturers working on coatings for cooking utensils such as in industrial bakeries.

At SPN, our expertise and experience, combined with our large fleet of machines and molds, allow us to provide you with the PFA parts and products you need. We offer high performance semi-finished products such as rods and bars, tubes and blanks, gaskets and washers and many other plastic components. We also produce finished PFA parts that meet and exceed your specific requirements.