PFA Turning

PFA Turning

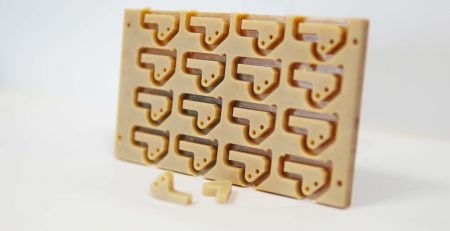

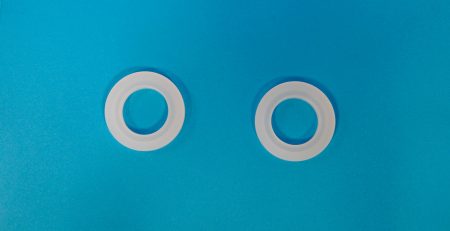

Turning of plastic components such as PFA is one of SPN’s specialities. The company is equipped with a selection of high-performance equipment to carry out this type of machining operation. For PFA turning, the company uses conventional lathes and mechanical lathes to machine the component according to customer requirements. PFA turning consists of rotating the component using a chuck. A turret equipped with a cutting tool then removes the unnecessary material. The precision of the operation depends on the size of the PFA. Like thermoplastic polymers, this material can be extruded or drawn for the design of pipes or tubes.

PFA or perfluoroalkoxy has similar properties to PTFE. The material has excellent heat resistance and can be used over a wide temperature range from – 220°C to 260°C. It is also appreciated for its low dielectric constant and its resistance to solar radiation. PFA also has excellent chemical resistance like PTFE. It remains unchanged under the action of ketones, bases and acids, hydrocarbons as well as alcohols. This fluoropolymer is often used in the pharmaceutical or semiconductor industry due to its near-zero moisture absorption property. This value is less than 0.1%. Its low electrical constant is also highly appreciated in electrical applications. Coatings made of PFA are also used in hostile areas subject to mechanical, thermal or chemical stress. PFA is also appreciated for its non-stick properties.