Polyimide molding

Information on the Polyimide molding at SPN

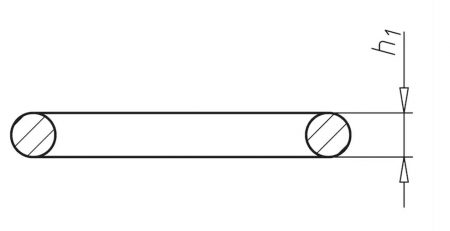

SPN carries out molding operations of Polyimides (equivalent to Vespel, Dupont’s trademark) by compression to produce blanks and obtain semi-finished products (bars, tubes, plates) or all types of specific shapes molded to measure according to the needs of our customers. We have a large number of molds at our disposal in order to select the most appropriate mold and consume as little material as possible. Our tubes, unlike solid bars, have the advantage of saving material, limiting environmental impact and cost. They can be machined by the SPN team or by the customer himself, at his convenience.

Polyimide offers many advantages and is widely used in the aerospace and industrial sectors. It offers excellent resistance to shocks, friction, creep and wear, as well as chemical inertness, even in contact with grease, chlorinated solvents, kerosene, refrigerant and lubricant. Its almost zero absorption rate, its cryogenic properties, its resistance to the effects of degassing, to thermal oxidation and its remarkable resistance to radiation. In addition, its low dielectric coefficient makes it a highly prized thermal and electrical insulator. Its high resistance to high temperatures (up to 340°C) makes it its main asset.