Polyimide Turning

Polyimide Turning

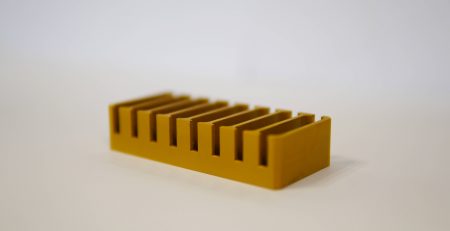

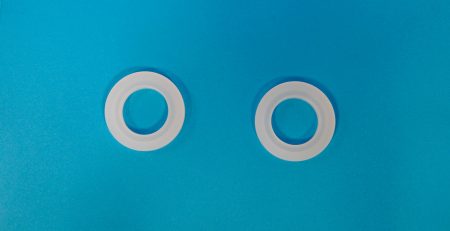

The SPN company has a complete and powerful equipment to carry out machining operations such as Polyimides turning. For this operation, the team uses conventional lathes and numerical lathes according to the customers’ requests. Polyimide turning consists in turning the material with the help of a mandarin. A turret equipped with a cutting tool then cuts the material. The precision of the operation will depend on the dimensions of the material and the technique used.

Polyimide or PI is a crystalline polymer. There is no glass transition or melting point below 500°C, which is its composition temperature. Polyimide is available in different grades and can be injected or compression moulded. It is used in the industrial and aeronautical sectors for its resistance to impact, friction, wear and creep. It remains unchanged in contact with chemicals such as lubricant, kerosene, chlorinated solvents, grease and refrigerant. Its low dielectric coefficient makes it a highly appreciated thermal and electrical insulator. It is resistant to the effects of degassing. It also has cryogenic properties that can reach -196°C. PI or Polyimide is highly resistant to radiation and thermal oxidation. SPN also transforms this material by moulding in order to design semi-finished products or components. SPN is involved in the turning of other materials with high temperature resistance and good electrical, mechanical and chemical properties such as PPS and PEEK.