POM milling

POM milling

SPN uses milling for the production of parts without an axis of revolution. The technique consists of fixing the material in a fixture or vice on a milling table. A cutting tool such as a milling cutter, a lathe or a drill then removes the excess material and defines the dimensions to obtain the part requested by the customer. The SPN team carries out two types of milling. Milling in 5 axis numerical control is recommended for parts with a lot of details. Conventional milling, on the other hand, is suitable for the manufacture of simple parts. All plastic materials can be milled and SPN offers POM milling.

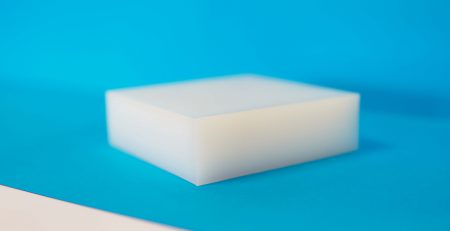

Also known as Polyoxymethylene or Polyacetal, POM is an opaque semi-crystalline plastic with a naturally white colour. However, it is often tinted. This thermoplastic polymer is available in two forms: POM-C (copolymer) and POM-H (homopolymer). POM-C is widely used in the food industry due to its resistance to strong bases, hydrolysis and degradation at high temperatures. It is easy to machine. POM-H is hard, rigid and resistant to creep. It has perfect tensile strength and absorbs very little moisture. This form of POM is ideal for use in the manufacture of building components requiring high stability. It is also in demand in small-scale mechanics and for the design of precision machine parts.

In general, POM is a material used for the production of parts with dimensional stability requirements. This thermoplastic polymer is used in the automotive, mechanical engineering and food processing industries.