PCTFE molding

Information on the PCTFE molding at SPN

SPN performs PCTFE molding operations for the production of blanks, semi-products (plates, tubes, bars) and specific designs transmitted by our customers (direct forming). The compression moulding process is as follows: the material is inserted into a mould and then placed in an oven to raise its temperature according to defined parameters. Once the mould and the material are at the chosen temperature, the mould is placed under a press and it is compressed while cooling down. This process allows a slow and controlled cooling for an optimal quality.

Using a large fleet of molds, we are able to perform compression molding of many PCTFE parts in order to meet the requirements and precise dimensions desired by the customer.

SPN notably produces tubes of all diameters (even beyond 500mm in diameter). Much appreciated because they save material and reduce cost, they retain the properties of PCTFE namely: low gas permeability, resistance to low temperatures and excellent chemical stability.

These qualities of this material in compression molding make it a popular material in many industries such as cryogenics, the manufacture of valves and even aeronautics. The blanks thus molded can then be machined by the customer or by the SPN team. PCTFE also offers, thanks to its chlorine atom which differentiates it from PTFE, excellent resistance to traction, creep and flammability. This plastic also has a high repellency and remains intact, including in the presence of certain oxidants, chemicals and aggressive active ingredients.

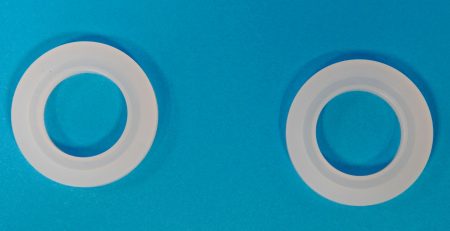

SPN manufactures machined parts (seals, non-return seals, valve seats, etc.) or semi-finished products (bars, plates, tubes) in this material.