PVDF Kynar

Kynar® PVDF is a range of materials manufactured by the Arkema Group. Kynar® is a well-known and recognized trademark, whose main component is polyvinylidene fluoride or PVDF. Thus, Kynar® PVDF inherits all the exceptional properties of this material. Parts machined from Kynar® PVDF are in great demand in many industrial sectors, especially for electric vehicle batteries.

Kynar® PVDF and its many interesting properties

The Arkema Group is one of the leaders in the PVDF market with its Kynar® range, which enables the manufacture of various parts based on polyvinylidene fluoride. SPN has chosen to use this range of material for the machining of parts, because the properties of Kynar® PVDF allow to meet many needs of the industrial sectors, in particular by its chemical inertia. Indeed, the stability and chemical resistance of Kynar® PVDF are among the best performing materials. It is a material that is perfectly resistant to almost all chemical agents, including acids, alcohols, chlorinated solvents, mineral bases and other aromatic hydrocarbons or aliphatic compounds. However, Kynar® PVDF is not recommended for parts that will be in direct contact with highly basic solutions such as ketones and esters.

Kynar® PVDF retains all of these properties well even at elevated temperatures: all properties, especially chemical properties, remain stable. Parts made with Kynar® PVDF perform well between -20°C and 130°C. Properties only start to degrade above 175°C. Also in terms of strength and performance, Kynar® PVDF is not sensitive to sunlight, UV and radiation. It also has gas-tight and non-stick properties. Finally, Kynar® PVDF parts have good resistance to aging: they are resistant to rubbing and abrasion.

Kynar® PVDF for parts in countless applications

Like Solef® and Dyneon® , Kynar® PVDF is in great demand in industries such as chemical, medical, pharmaceutical, food, aerospace and other sectors that use parts machined from Kynar® PVDF. But other sectors also benefit from the properties of Kynar® PVDF. The electronics industry, for example, uses this material to make insulators or to manufacture piezoelectric parts.

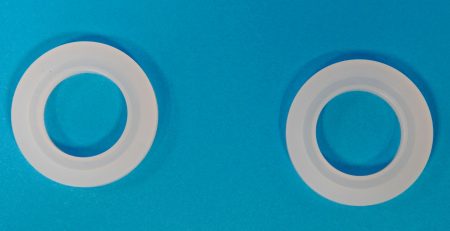

So you can entrust SPN with your specifications for the manufacture of your PVDF parts. Thanks to our expertise in the transformation of plastic materials and also to our high-performance machinery, we can create parts adapted to the needs of your activity. We have mastered the processes for transforming Kynar® PVDF by compression molding, milling and turning.

Do you need specific or standard Kynar® PVDF parts? Give us your project and we’ll make your custom parts to suit your needs. On our website, you can easily get in touch with our experts.