Tefzel ETFE

To manufacture critical parts such as valves and seals for extreme industrial applications, Tefzel™ ETFE resins are emerging as the ideal material with technical characteristics to meet the severe requirements.

Key technical characteristics of ETFE

Tefzel™ ETFE or ethylene tetrafluoroethylene resins have many interesting properties. But in general, ETFE is best known for its ability to resist UV, gamma rays. It also shows good resistance to impact, as well as to stress cracking.

Moreover, ETFE is able to support loads 400 times its mass. Perfectly recyclable, this thermoplastic also displays excellent chemical resistance. However, this is still inferior to that of PTFE. If Tefzel™ ETFE resins are very much in demand, it is because of another characteristic. It is its semi-crystalline aspect which gives it the ability to transmit light perfectly. ETFE can be used to replace glass, especially in the building industry. In addition, this thermoplastic fluoropolymer has the advantage of being much lighter than glass. The density of glass is 2.5, while that of ETFE is only 1.7. As a reminder, Tefzel™ is the trademark of Dupont.

Possible applications and uses of ETFE

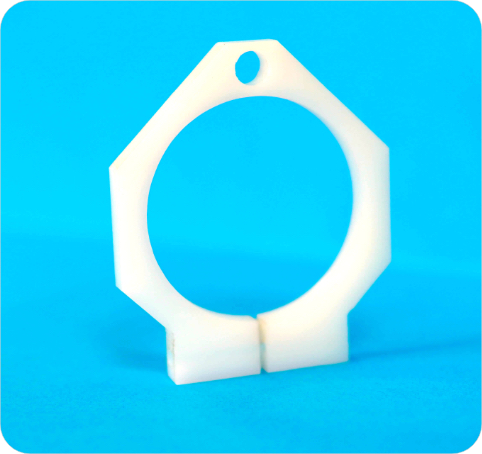

Tefzel™ ETFE resins are an essential component in the manufacture of various components and parts. For example, Tefzel™ ETFE is useful in the manufacture of mechanical parts of all kinds, including valves and fittings. This plastic material is also widely used in the chemical industry, particularly because of its ability to retain its properties even when continuously exposed to high temperatures.

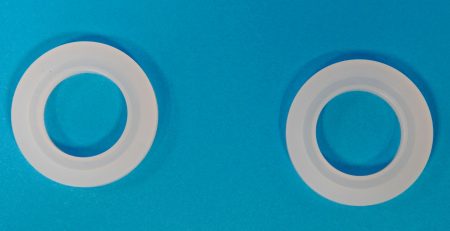

In addition, Tefzel™ ETFE resins are a material of choice in the manufacture of gaskets and linings used in the construction industry. Very popular in the construction fields, Tefzel™ ETFE resins appeal as much for their easy-to-handle characters as for their translucent property: it is a good alternative to glass.

Need specific products or Tefzel™ ETFE parts with custom dimensions? Call on the services of our company SPN. We specialize in the machining and processing of various plastic materials. At SPN, we only process high-performance materials. This is the case with Tefzel™ ETFE, but also with filled PTFE, PSU, PVDF, PEEK or even PFA. These are, among others, examples of very high performance materials that we can work with. To transform these materials, we use techniques such as extrusion, compression and molding. In addition, we prefer turning, milling and cutting.

In addition to standard parts, we are also able to manufacture custom-made parts. Do not hesitate to contact our experts at 01 48 45 49 79 or for more information. You can also use our contact details and our online contact form, either for information or to request a quote.