The advantage of PCTFE in the use of gaskets for LNG (liquefied natural gas)

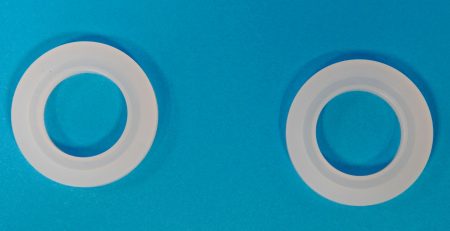

In terms of cryogenic sealing, two main polymers used on the market are : PCTFE or PTFCE – polychlorotrifluoroethylene – and PTFE – polytetrafluoroethylene – and more specifically MPTFE, i.e. modified PTFE (TFM® or NXT®).

These polymers are very much in demand, particularly in cryogenic sealing systems, thanks to their properties at very low temperatures. They offer better ductility and also important load-bearing characteristics in environments where all other materials are very brittle, including metals.

In terms of the choice of sealing material for cryogenic valves, many characteristics are required, namely :

- rigidity characteristics adapted to obtain effective sealing at very low and ambient temperatures,

- Fast recovery after load removal,

- high wear resistance and low friction,

- Toughness and strength depending on the application,

- Low thermal expansion to avoid thermal mismatch with adjacent metal components,

- high thermal conductivity to allow rapid temperature equalization with all surrounding components.

- the widest possible operating range of temperature and pressure.

LNG – Liquefied Natural Gas – is a mixture of hydrocarbons composed mainly of methane, but with varying levels of ethane, propane, butane and other gases present in natural gas. In general, LNG has a boiling temperature between -166°C and -57°C at atmospheric pressure.

However, in practice, when temperatures drop, a decrease in resistance is often always observed. The reason for this is that low temperatures cause a loss of flexibility which can lead to brittle fracture before the elasticity threshold is reached.

A chemical environment can also have a significant effect on the properties of the polymer exposed at low temperatures, in the same way that solvents can promote cracking of polymers at high temperatures.

Lower temperatures produce a progressive increase in tensile and flexural strength and stiffness, creep and fatigue resistance, and dielectric strength and rigidity. On the other hand, there is also a progressive decrease in elongation, impact strength, tensile strength, compressive strength, CLTE or Coefficient of Linear Thermal Expansion, and permittivity/dielectric loss factor.

Over the years, many materials, including various steels and other non-ferrous alloys, have been developed so that their strength and all their properties are not altered and are maintained at extremely low temperatures. In the case of polymers and elastomers, their behaviour is dictated by the positions of the main thermal transitions and the molecular movements/rotations associated with them. Among the polymers most used in the field, we often find fluorinated polymers such as PTFE, PCTFE, FEP) but also various elastomers and polymers that have specific formulas so that they can maintain ductility at very low temperatures. But many other materials have been specifically formulated for such extreme conditions, PCTFE and MPTFE are the most commonly used materials.