Turning PA66

Turning PA66

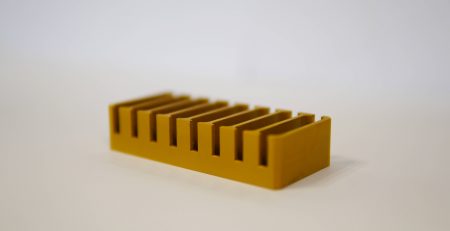

SPN offers its services for all plastic component turning operations. SPN is equipped with various machine tools for such operations. The SPN team uses conventional lathes or numerical lathes for the machining of these plastic parts, this is done according to the specifications of its customers. The company works with many high-performance plastics, such as PA66. Like the turning of other high-performance plastics, PA66 turning is also carried out using a chuck and turret. The accuracy of the process depends on the dimensions of the workpiece and the technology used.

PA66, also known as polyamide 66, is a plastic with excellent physical properties. It is rigid, hard and abrasion resistant. It has excellent wear and friction resistance and has a damping property. PA66 is also resistant to impact and chemical corrosion. Although very strong, this material is easy to weld and bend. It is inert in contact with oils, greases and fuels.

Compared to PA6, however, PA66 absorbs more moisture when saturated. It is available in extruded form and is used in the electronics industry for the design of housings, sockets or coils. In the automotive industry, it is used in the manufacture of brackets, headlight components, oil and fuel filter tubes and in tank design. PA66 is also used for guide channels and in mechanical engineering for sliding bearings and gear wheels.